Customer experience is king

Chilled Product optimized 24/7

Store safety is a No1 priority

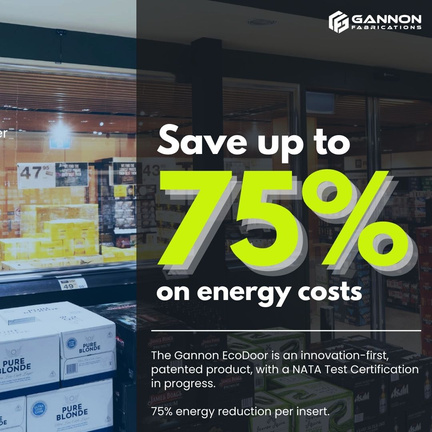

Saving energy by at least 70%

Our test room operates 24/7.

How we test? Our frames are installed in a cold room running at 2 degrees, in a 90% humidity environment. We monitor standard aluminium frames with the Gannon EcoDoor.

The results: a regular 3 door frame requires 0.8kw energy to prevent condensation, compared to 0.2kw with the Gannon EcoDoor, to achieve the same outcome.

Every glass insert system is rigorously tested for performance, operation and electrical safety.

Fixing is through the front, so no need to flash the opening to fit the frame through the side. Finished with a sleek snap-fit cover, less material, less labour, less time required on site, reduced costs.

Our innovation first poly-amide struts have less than 1% heat transference, compared to industry standard aluminium frames at approximately 100% heat transference. The innovation isolates heat the refrigerated area from the ambient side, where it is required the most. As you can see, a picture says a thousand words.

A rubber gasket prevents ‘air ingress’; air penetration to the ambient side when the door is closed.

Gannon struts react to temperature the same rate as aluminium. Contracting and expanding equally, ensuring no thermal cracking. This is the cause of other frames in the market, to become faulty. GANNON inserts last 15 years +

Innovation first is an insulation core fitted inside the frame to enhance performance, allowing a small corridor for wiring. This is designed to prevent convection inside the cavity.

Have a question?

We’d love to hear from you!

Fill in your details and we’ll get back to you in no time.